Detecting Abnormal EV Battery Usage in Fleets

10 July 2023

Read time: 4 min

How can electric vehicle (EV) fleet managers track abnormal battery usage?

Battery electric vehicles (BEV) typically use rechargeable lithium-ion batteries which are the most costly component of a BEV and one of the most important. It is needed to start the vehicle, run the air conditioning, listen to music, wash the windscreen and turn on the headlights at night.

The battery capacity of the vehicle determines its usable range. A degrading battery affects not only the range capacity of the vehicle but also reduces the cost savings of EV charging. Therefore, it’s essential to keep an eye out for abnormal changes in battery usage based on mileage to maximize usable range over time.

Pitstop has developed the EV Model to examine how batteries have held up over time and to detect abnormal battery usage that would help assess the health of an EV battery. Continue to read to learn about the health of EV batteries and key takeaways on fleet battery performance.

What is the Life Expectancy of a Truck EV Battery?

Lithium-ion batteries last 8 years or 100,000 miles on average; however, it is not that simple. The lifespan can change based on storing and operating temperature, manufacturing defects, charge-discharge cycles, and time. Failing to identify battery faults can further harm the battery’s expected lifetime. For example, a battery could have a circuit malfunction, causing it to leak, and without proper maintenance, can depreciate its performance.

Nevertheless, warranties are encouraging for fleet electrification fleet managers, and the cost of batteries is reduced yearly. With the assurance of automakers’ EV battery technology and lower prices, there is a promising future for EV adopters.

What is Normal Battery Capacity?

The average battery capacity for a BEV is around 40kWh (Kilowatt hours), but some vehicles now have up to 100kWh capacity. Today we see BEV models on the market that promise a minimum of 300 miles in total driving range when battery capacity is normal.

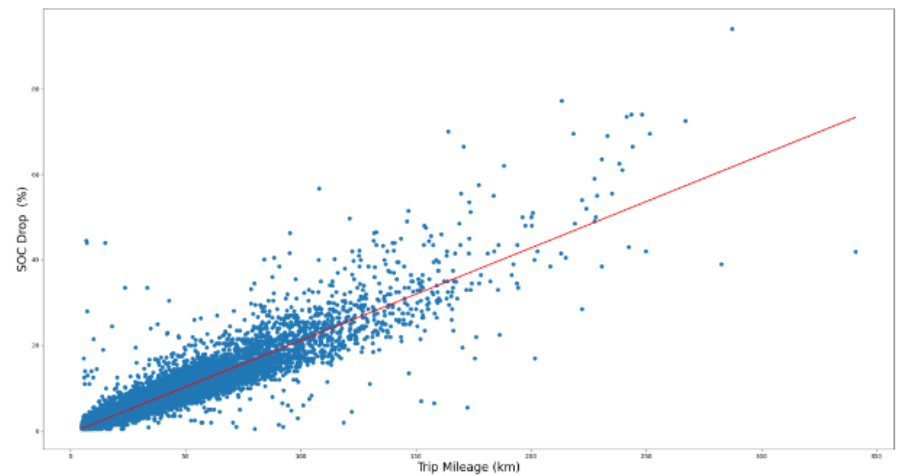

A way to determine normal battery capacity would be to look at the State of Charge (SoC) drop relative to trip mileage for a number of similar BEVs. We expect a graph of SoC drop vs. trip mileage to be linear the greater the trip mileage, the greater the SoC drop.

Figure 1 above shows this trend from 400 fleet BEVs from Pitstop’s fleet tracking software along with the regression line (in red).

The red trend line is now the ”normal” or ”baseline” to which new trips are compared. The normal line also takes into consideration the predicted versus actual SoC drop. Looking at the graph, any blue dot near or below the normal line detects normal battery usage within the trip. However, we cannot assume that one trip of abnormal battery usage means the battery has degraded.

Alerting Abnormal Battery Usage

A single trip having abnormal battery usage doesn’t warrant an alert being sent to the driver. There could be circumstances unique to the trip that could’ve led to it being classified as such. For instance, data abnormalities (telematics issues), traffic, weather, and driver error (ex., accidentally leaving the vehicle turned on). However, numerous anomalous trips in the short and medium term could be an early indication of potential battery issues with the vehicle.

There are two alert windows Pitstop issues to the driver. The first is a short warning. If several anomalies occur within 24 hours, this alert suggests the driver be attentive to battery usage over the next few weeks.

The second alert is a long warning that notifies the driver of multiple trips with abnormal battery usage during the past week. If this is the case, the electric vehicle fleet manager should schedule maintenance to determine if there are major battery issues.

If both warnings are issues, Pitstop will prioritize the long warning as it’s a harder threshold to exceed and a better indicator of a degraded battery.

EV Fleet Maintenance Management

This SoC anomalous drop detection method is a form of predictive fleet maintenance for BEV batteries. Predictive maintenance helps determine vehicle failures before they happen, reducing downtime and saving on fleet maintenance costs.

You can prevent battery issues by:

- Avoid leaving your BEV parked on an empty charge, and keep your SoC between 20-80%

- Avoid extreme weather conditions when possible, such as parking your BEV outside on a hot summer day

- Avoid using fast-charging stations, preventing discharge of an extreme state of charge

- Use a predictive fleet maintenance software alongside regularly scheduled maintenance to check in on your BEV battery’s state of health

Final Thoughts

Don’t sweat over the small stuff; losing some capacity may not affect your daily driving requirements when bigger battery packs are introduced in cars, and it shouldn’t overshadow the many advantages that EVs have to offer.

Are you planning to do fleet electrification or improve your EV fleet’s operations? Learn how our predictive technology is paving the way to help businesses meet emission standards and optimize vehicle performance at scale by booking a demo.

About the Author

Shyam Krishnan is the Lead Data Scientist for Pitstop, a powerful predictive maintenance software for the transportation and automotive industry.