“Smart” Preventative Maintenance - A new way to think about Fleet Maintenance

21 February 2023

Read time: 3 min

Align PMs with Vehicle Health

The majority of fleets have a Preventative maintenance (PM) program implemented; either this program is scheduled based on mileage and time, or in rare scenarios, it is based on engine hours, especially for fleets with a high idle time. These PMs are usually programmed into a maintenance platform or part of an excel spreadsheet. In most scenarios, the fleet managers will get notified as soon as the PM service needs to be performed.

Fleets experience unexpected breakdowns with static PMs

At Pitstop, we have analyzed many work order records for various fleet sizes (100 to 5000 vehicles) across multiple years. As a result, we have uncovered a notable trend that the vehicles frequently have a high risk of failure a few weeks before the scheduled visit or after the PM has been completed. As a result, Pitstop has built analytics tools that leverage work order data and telematics data (sensor data, fault codes) to uncover insights into the breakdowns that could have been avoided. Or if the problems were addressed at the time of the PM visit or if the PM visit should have been readjusted based on the issues that had been identified before the visit by Pitstop.

We observed that when the vehicle was booked in for PMs, the shop only followed what was needed for the PM visit rather than checking the other active issues on the vehicle. Example: If Pitstop’s algorithm had flagged that the diesel exhaust system and battery needed to be inspected on the next service visit or if the vehicle had active fault codes, we noticed these were still active issues after the PM visit. We discovered that adjusting the PM date could have prevented some of the failures.

Introducing: Smart Preventative Maintenance

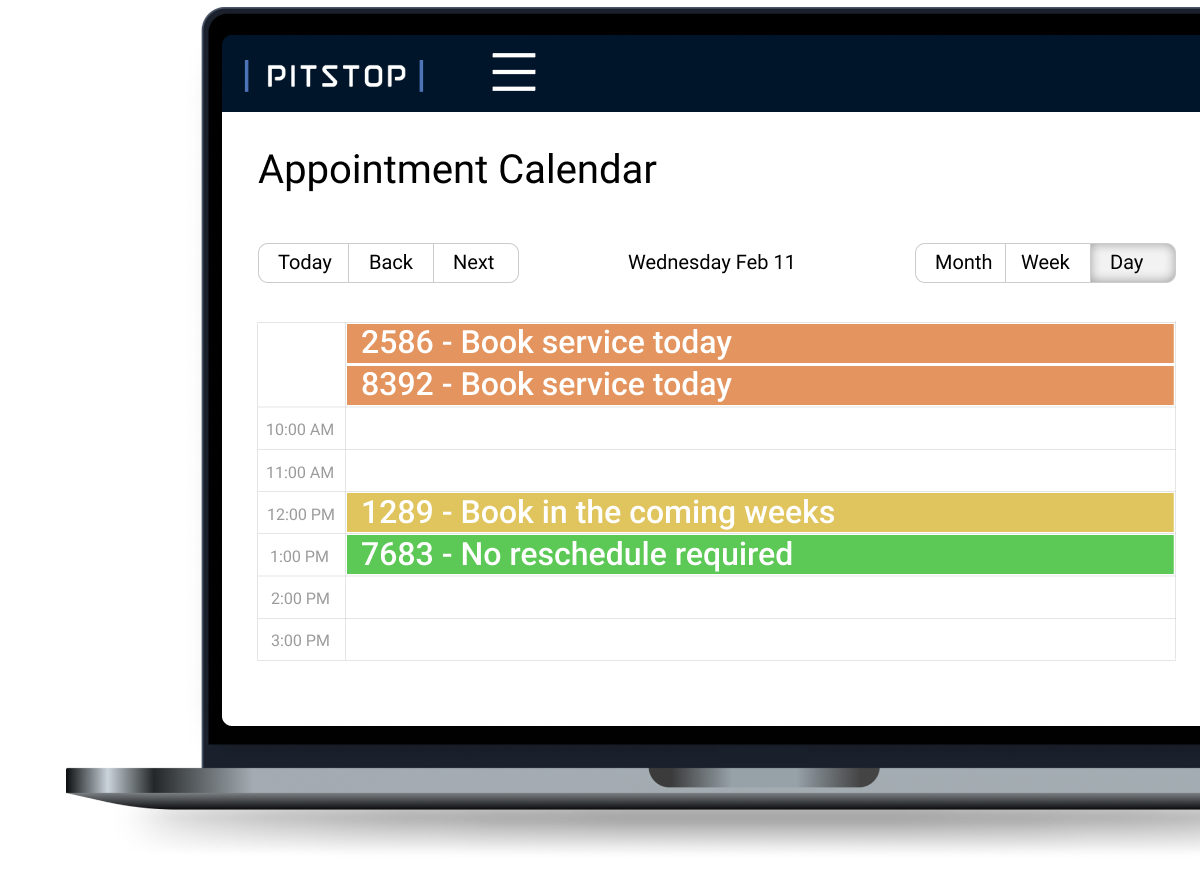

In order to tackle this, we have released a new feature that automatically takes in all of the PM schedules and informs the fleet manager if the PM needs to be readjusted, and guides the user to make a decision accordingly. We have made it extremely easy for the fleet manager to view this information by layering this information on our existing Appointment Calendar. The view tells the user about the state of the vehicle and the action the user needs to take and has color-coded this to make it extremely easy to understand. The user can drag and drop the appointments on the calendar to readjust the dates and can view how busy the shop is at a particular given time. The view also tells the user if the vehicle is in healthy condition, so if the shop is overbooked at any given point in time, the fleet manager can choose which vehicle should take precedence using the Smart PM feature.

We have already launched this feature with dozens of fleets and have seen some incredible results in terms of cost savings and reduced breakdowns. The concept of PMs has truly evolved from being static to smart by leveraging AI and insights that are now available through the widespread use of telematics. We are confident that this feature will drive value to any fleet with telematics and a fixed PM schedule. We have seen that the total average number of service visits for a vehicle has significantly decreased for fleets that have changed their maintenance strategy from planned to proactive and predictive in nature. It is financially impactful to a business to reduce even one shop visit with today’s rising maintenance operations,

Pitstop has built internal tools to help audit your fleet’s existing PM program by leveraging work order and telematics data. This will give you a better understanding of how issues are being addressed at the shop level and whether your fleet could benefit from Smart PM.

About the Author

Vedant Khattar is the Chief Technology Officer for Pitstop, a powerful predictive maintenance software for the transportation and automotive industry.