2024: The Year to Embrace AI in Your Fleet Management Strategy

Artificial intelligence (AI) was the industry disruptor everyone talked about in 2023, and it continues to reshape the landscape as we forge into 2024. This year, AI isn’t just buzzing in the media; it’s the powerhouse behind substantial efficiencies in fleet management. With 84% of fleets expecting to implement generative AI into their operations by the end of this year, the revolution in fleet management is here. Companies are no longer questioning if AI can be of value; instead, they are exploring the numerous ways AI can supercharge their fleet’s efficiency, reliability, and overall performance.

The State of AI Adoption in Fleets

In 2024, artificial intelligence will become a robust tool vital for the modernizing of fleet management. Pioneering organizations are witnessing AI’s potential to transform their operations from reactive to proactive.

The rise of AI in fleet maintenance can be attributed to the growing availability of data. Digitalization, driven in part by the Electronic Logging Device (ELD) mandate, has led to a massive influx of data. This surge in technology adoption has resulted in fleets having access to more data than ever before. However, managing this data efficiently has become a major challenge.

This is where AI steps in. AI can quickly and accurately process vast amounts of data, making it valuable in fleet operations. What does implementing this AI solution actually mean for your team? Whether it’s an analyst or the fleet manager handling the review of fault codes, idling, and other driving behavior data, AI can significantly reduce the workload. In fact, it can alleviate approximately 80% of the analytical tasks, streamlining your operations and allowing your team to focus on more strategic aspects.

Real-World Applications and Insights

Artificial Intelligence is transforming fleet management, with practical applications leading to remarkable improvements in maintenance, efficiency, and cost savings. Here are just a few of the applications of AI that fleets are currently using today:

- Dynamic Maintenance: Traditional preventative maintenance (PM) schedules assume that you don’t know the state of your equipment remotely, leading to over-maintaining and unnecessary downtime. AI-powered dynamic maintenance uses predictive insights to focus on the health of individual vehicles, allowing for more efficient resource allocation and cost savings.

- Predictive Analytics: AI can analyze historical, current and future data from multiple sources to produce predictive insights on vehicle performance. These predictive insights can help fleet managers, technicians, and drivers more efficiently plan for downtime without causing expensive disruptions.

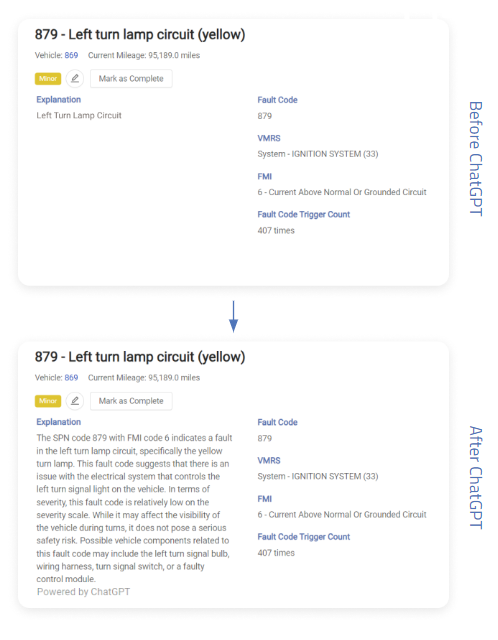

- Remote Diagnostics: AI can analyze fault code alerts and prioritize them into critical, major, and minor issues. This helps technicians focus on critical tasks and avoid manually sifting through hundreds of alerts.

- AI Fine-Tuning: AI continually refines its processes based on data and human feedback, becoming more accurate and impactful over time.

- ChatGPT Issue Descriptions: In addition to remote diagnostic, AI can translate complex fault codes into easily understandable language, facilitating communication between drivers, technicians, and the maintenance team.

As more fleets start using these solutions and give feedback, we will see more useful features and improvements in the future. This ongoing traction will lead to tailored enhancements addressing unique needs, and continual technological advancements will further refine and expand the capabilities of these solutions.

Quantifying AI’s Return on Investment: Case Studies

Case Study 1: Optimizing Shop Efficiency

The City of Long Beach fleet of 600 assets, including a mix of vehicles and equipment, relied heavily on driver-reported issues, which often led to unexpected breakdowns and costly service visits. The City was spending approximately $650,000 per quarter on preventive maintenance (PM) alone.

By implementing AI-powered dynamic PM scheduling, the fleet experienced a remarkable transformation. AI analyzed telematics data and provided predictive insights, enabling the fleet to focus on individual vehicle health.

“The AI insights feature identified a report history of any battery issues and a result score history with an easy-to-read graph that demonstrated a two-week failure probability. There were also other systems that were monitored in the same fashion. A brake usage percentile score, cranking voltage reading/test, and one of my favorites is the parked vehicle history that verified days since last driven,” said their light line equipment technician.

This allowed them to avoid unnecessary shop visits and part replacements. As a result, shop efficiency improved by a staggering 177%. The fleet not only saved on maintenance costs but also increased public safety by reducing unexpected repair visits. The annual cost savings amounted to over $800,000.

Case Study 2: Proactive Problem Solving

The fleet manager from the City of West Jordan expressed the benefits of using AI to analyze their vehicle data, stating, “A lot of times, the best part of it was being able to see stuff that we don’t get from the drivers, and have them come in before they have a breakdown or a problem. We can schedule the vehicles when they aren’t using them, instead of having to go and figure out why it stopped on the side of the road.”

He elaborated on the effectiveness of integrating Pitstop’s AI platform with their telematics provider, Geotab. He recalled an incident where a truck was brought in on a Friday with a check engine light on. Thanks to the AI-driven insights extracted from their vehicles, the technicians were able to quickly identify and replace the faulty O2 sensors, returning the truck to service by Monday. “That was one of those times where AI showed us exactly what we needed to do,” he commented. “We knew exactly what we were looking for and got the part that we had to change.”

The fleet manager further noted the importance of customization in technology, saying, “It’s not a silver bullet. The more that you can customize it, the more that it learns about your system, and the more you get to have alerts that actually mean something and aren’t just for a random code from your vehicle.” For the entire testimony, watch our webinar AI Revolution in Fleet Maintenance.

Fostering AI-First Culture in Fleet Management

AI is no longer just a buzzword; it’s a powerful tool that can supercharge fleet operations. Whether it’s preventive maintenance, remote diagnostics, or communication with drivers and technicians, AI offers a transformative solution. Fleets are facing growing challenges and increasing costs, and AI provides a solution that not only saves money but also enhances safety and efficiency.

As we step into 2024, consider harnessing the power of AI to optimize your fleet maintenance operations and stay ahead in the ever-evolving world of fleet management. It’s not just a trend; it’s a transformation that can make a real difference in your bottom line.