Predicting A Transmission Failure With Accuracy

06 February 2024

Read time: 3 min

Case Study

Overview: AI and ML Technology in Predictive Vehicle Health Monitoring

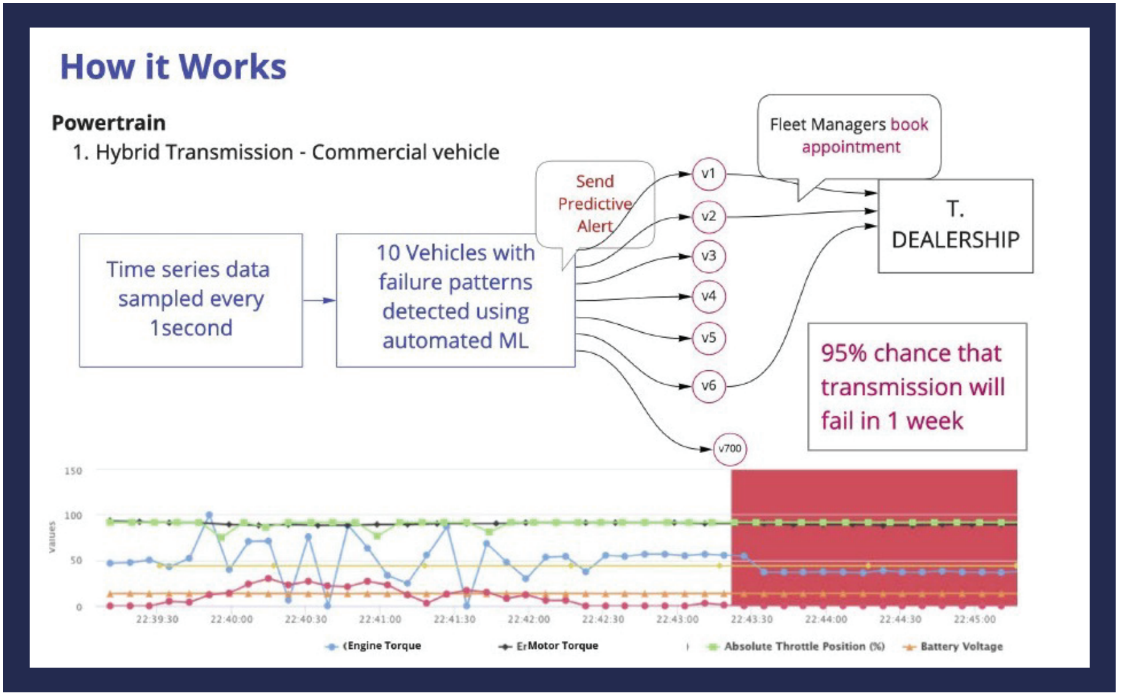

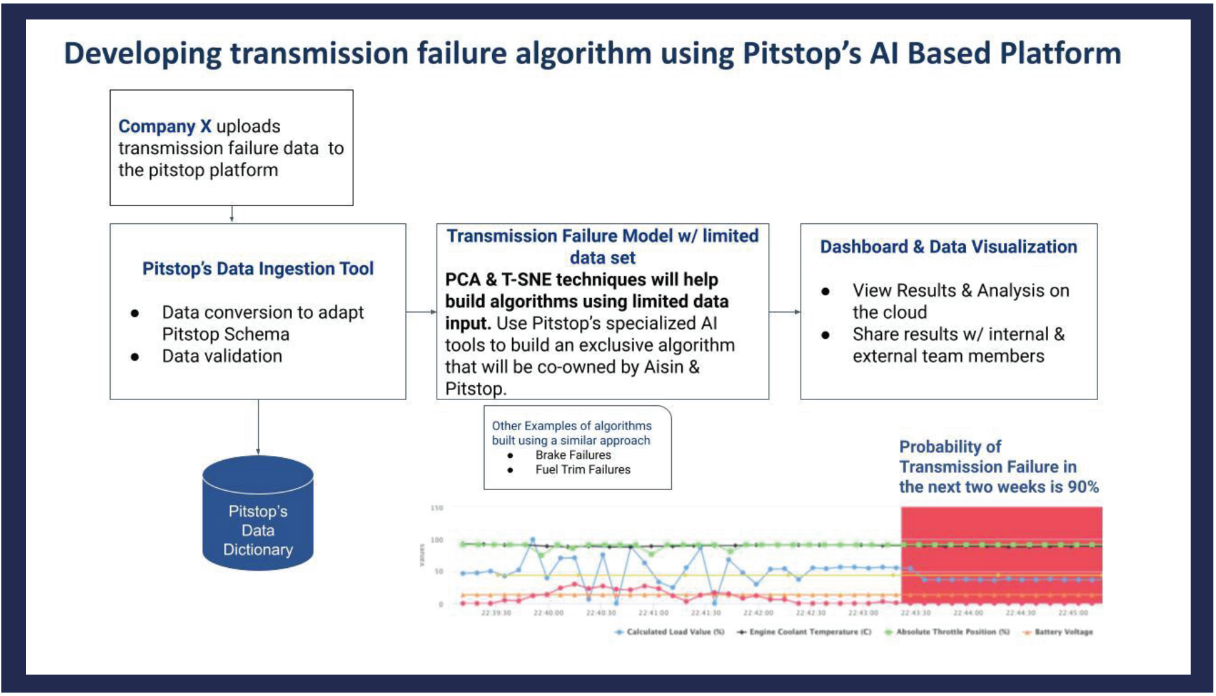

One of the world’s largest global transmission manufacturers (Company X) partnered with Pitstop to build a predictive algorithm leveraging innovative AI technologies which targeted performance in the field and end-customer safety. Using the latest in artificial intelligence and machine learning technology (AI and ML), Pitstop’s advanced analytical models were successfully created through predictive maintenance software, allowing Company X the opportunity to save millions of dollars in costly recalls and warranties and drastically improve customer experience by predicting a hybrid transmission failure before it happens through vehicle health monitoring.

Challenge 1: Multi-Use Case Predictive Algorithm

Problem

Company X experienced a hybrid transmission failure in the field and wanted to determine whether a predictive algorithm could have detected the failure in advance. Because Company X operates in many regions of the world and produces many different transmissions, the algorithm would be more useful and valuable if it could be applied to different transmissions or use cases. To achieve this goal, the algorithm needed to avoid using specific engineering knowledge.

This requirement posed a problem because it does not permit the application of the conventional engineering approaches, or even conventional feature engineering, often used in machine learning approaches. For example, analysts were unable to label variables such as pressures, rotation rates, and forces. Therefore, it was not possible to develop any dynamic equations or apply any domain-specific theories, complicating the process.

Grouping of the variables provided was done using only statistical features.

Solution

To solve this problem, Pitstop developed a statistical approach to feature engineering, combined with general insights into the failure of mechanical systems. This led Pitstop to develop an algorithm that did not need any specific transmission focus, allowing it to be applied to multiple contexts. The techniques used included principal component analysis and some techniques from the theory of dynamical systems.

Challenge 2: Delivering Under Time Constraints

Problem

Pitstop was given three months to complete this project. This process included gathering and exploring the structure of raw data and building templates to recognize candidate features. The resulting conclusions were developed into an analytical model that could be implemented as clear and portable code.

Solution

Pitstop assigned this project to a team of experienced data scientists and senior developers. They utilized the existing Pitstop platform which allowed them to automate data intake, organize service architecture, provide easy data visualization, and enable final predictive algorithm validation.

Pitstop’s customer success team helped familiarize Company X with Pitstop’s platform and its features. They bridged the communication between the two parties, ensuring that their questions were answered and their needs met.

The platform’s capabilities in automating data intake, simplifying data visualization, and facilitating code portability were crucial in developing a robust solution for vehicle health monitoring within the tight timeframe.

Results: Enhanced Performance and Customer Safety Through Data Science Solutions

Using Pitstop’s algorithms, Company X successfully increased its ability to efficiently improve performance in the field and end-customer safety through the following:

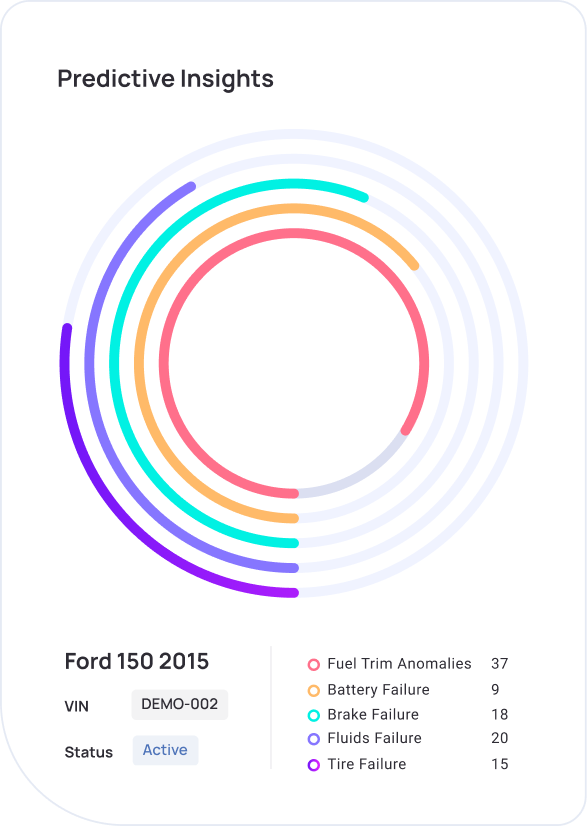

- Improved performance for specific vehicle transmissions, capturing vehicle failures before they happen in real time.

- The opportunity to provide a better user experience by sending predictive alerts about vehicle health, reducing vehicle breakdowns significantly.

- Saved costs and resources on recalls by catching failures ahead of time.

- Provided engineers with the Pitstop dashboard to develop predictive methods to visualize the data and take action, while saving time on development.

Outcome: A Testament to AI and ML Innovation

Pitstop successfully delivered a high-accuracy algorithm and dashboard for a large global transmission manufacturer in 12 weeks. Company X was highly satisfied with the outcome and its overall partnership with Pitstop.

This partnership not only led to increased operational efficiency and customer satisfaction but also set a new benchmark for the application of AI and ML technology in the automotive industry.